How Industry 4.0 is Transforming the Oil & Gas Supply Chain

The path oil and gas travels from extraction to end consumer is in a state of transformation. Operations are changing at every link in the supply chain, as companies adopt new and emerging technologies, digitize their enterprises, and streamline processes.

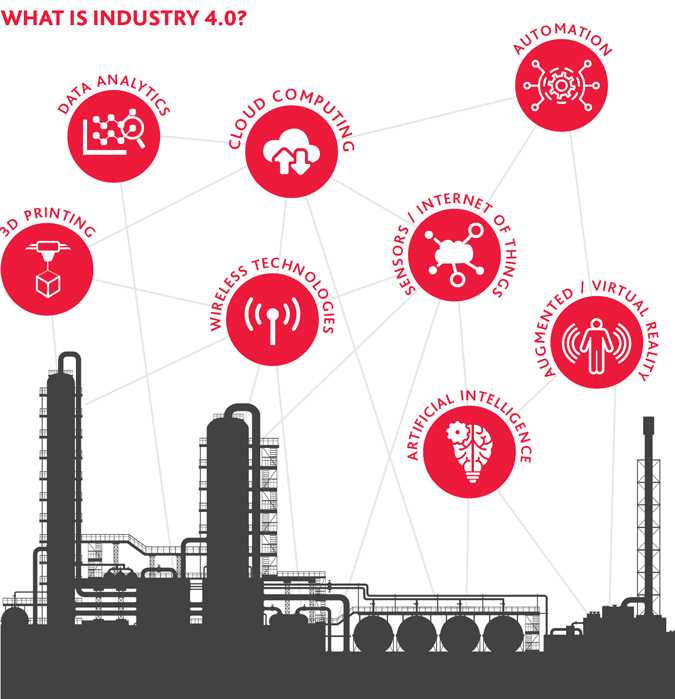

Larger than just one company, or even one industry, it is a full-scale revolution: the fourth industrial revolution, or Industry 4.0. Borne out of a confluence of technology disruptions—including Big Data, analytics, the Internet of Things (IoT), augmented reality, and artificial intelligence—Industry 4.0 ultimately hinges on the ability to integrate data with physical processes.

A LOOK AT THE OIL FIELDS: HOW TECHNOLOGY IS DRIVING U.S. SHALE GROWTH

For evidence of technology’s power to revitalize production, look no further than the rampant growth of U.S. shale. At CERAWeek 2018, the Organization of Petroleum Exporting Countries (OPEC) Secretary General Mohammad Barkindo credited U.S. shale producers—competitive suppliers—for effectively leveraging technology to dramatically boost production. The Energy Information Administration (EIA) forecasts that the nation’s shale production will increase 25 percent in April, with an estimated output of 6.95 million barrels a day.

Horizontal drilling is by no means a new technique and not an example of digitization in the oilfield. Rather, it is enhanced data collection—driven by advances in seismic imaging—and data analysis that is leading to greater precision once drilling begins. Oil and gas companies’ ability to replicate and sustain early successful digitization initiatives will be key for cutting costs and maximizing output—an important goal in a volatile industry.

While shale producers are a standout example of technology’s potential, they are certainly not the only energy players taking up arms in the revolution. To illustrate how Industry 4.0 is changing the traditional journey oil and gas takes as it moves through the supply chain, we highlight select examples of both incremental and wide-sweeping changes at each stage in the supply chain.

ACROSS THE SUPPLY CHAIN

Maintenance and Safety

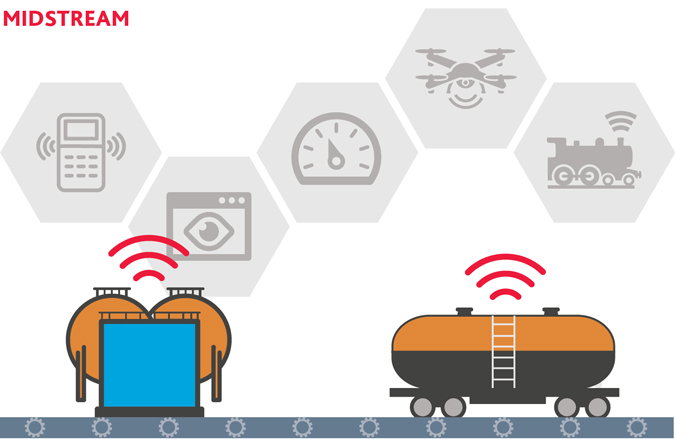

Boasting a true eagle-eye view, drones are eclipsing traditional inspection methods and facilitating early detection of oil and gas leaks in difficult-to-access locations, like offshore drilling sites. In the midstream sector, drones equipped with thermal imaging systems can help identify points of vulnerability across the nation’s 2.4 million miles of pipelines.

Increased Connectivity

Increased data integration and information sharing up and downstream could allow companies to adjust production levels in real time, based on inventory data from storage facilities, rate of distribution, and forecasted demand.

Exploration

A core part of exploration, seismic imaging is a process already rooted in data analytics and 3D visualization models. Exploration and production (E&P) companies moving into the next generation of seismic imaging are experimenting with 4D models that integrate production data to map changes in reserves’ oil and gas levels. These advances aim to more precisely pinpoint the quantity of resources and the lifespan of each well.

Production

The digitization of drilling processes is a potential goldmine for oilfield services (OFS) firms. Applications gaining ground among E&P companies, and a few of their benefits include:

-

Leveraging data from software sensors to determine which drilling methods combine the right mixture of sand, water, and chemicals to maximize a well’s output.

-

Automated drillers to increase production and reduce costs.

-

Drilling equipment embedded with smart sensors to collect data.

The X-Factor: Integrating data collected from disparate drilling tools, often housed by different OFS vendors, to analyze the full picture of a company’s production.

Storage

Key areas of transformation include improvements in data management to track inventory levels and monitoring systems to automate temperature control.

Transportation

Equipping railcars and tracks with smart sensors and thermal detectors can provide real-time geolocation data and monitor key safety features to minimize the risk of derailments.

Pipelines with smart sensors can detect leaks early and monitor variables such as pressure, temperature, and any deformations in the pipeline’s infrastructure.

Refining

Smart sensors enhance monitoring the safety and functionality of all processes.

Distribution

Predictive analytics equip companies to forecast demand with greater accuracy, seamlessly communicate data throughout the supply chain, and automate production levels.

What’s next?

Examined individually, the deployment of new technology at each level of the supply chain can improve a single process and increase profits for a single company. But combined, the innovations could transform an industry. The true power of digitization and the heart of Industry 4.0 is the way that siloed technological advances connect and communicate to create a shared data ecosystem.

The arrival of Industry 4.0 is heralding the next era in supply chain management, in which suppliers and customers come together in entirely new ways, erasing organizational boundaries. The traditional linear supply chain is evolving into an integrated value chain of mutually beneficial relationships where suppliers and customers collaborate to achieve efficiencies and lower costs by exchanging information and securely integrating systems and processes.

The potential is vast. Digitizing the supply chain can reduce procurement costs for all purchases of goods and services by 20 percent, reduce supply chain process costs by 50 percent, and increase revenue by 10 percent, according to the Center for Global Enterprise.

While the fourth industrial revolution in oil and gas is still in its infancy, the way that energy companies integrate their data, communicate, and work together will continue to converge, evolve, and transform.

SHARE